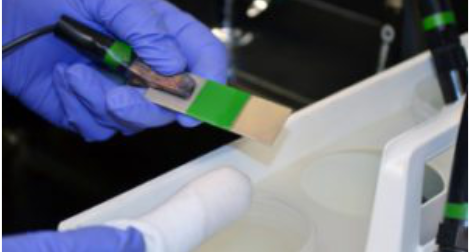

Brush plating, or selective plating, is a method of electroplating on a localized area without the use of an immersion tank. It is primarily used for enhancing surfaces on OEM components, permanent repairs and salvaging worn or mis-machined parts.

In a typical operation, the part is first masked and then a series of base material-specific preparatory steps are conducted to ensure an adherent deposit. The last step is the plating of the metal deposit to the desired thickness.